EN 374:2016 – Chemicals and Micro-Organism Protection

Working with chemicals and micro-organisms can be very high risk, which is why it is so important to ensure that the wearer has the correct pair of gloves for the job at hand. That’s where EN 374:2016 comes in. The standard rates the performance of a glove against chemical risks and tests its ability to prevent mico-organisms and viruses from entering the glove.

There are numerous tests that are run under this one standard and up to 4 different icons that can be reflected on the markings, making it quite an intimidating standard. This article hopes to break down and explain each of the tests within the standard to enable you to make a more informed decision when selecting your next pair of gloves.

Requirements for Chemical and Micro-organism Protective Gloves

- There are 3 main tests that are performed when testing the performance of a glove against chemical risks and micro-organisms.

- If a glove is required to protect the wearer against Viruses, an additional test will need to be done.

- If a glove is longer than 40cm, these 3 tests must also be performed on the cuff area.

- The penetration test examines the movement of a chemical or micro-organism (bacteria/ Fungi) through a glove to ensure that it is free from holes / cracks / or has any weaknesses in its seams.

- There are 2 tests that are performed here:

- The first test is the air leak test. Here a glove is filled with air and submerged in a tank of water (placed under the water) to see if there are any leaks or weaknesses within the gloves material or make up.

- The second test involves hanging a glove filled with water and checking to see if any of the water passes through (penetrates) the glove.

- This is a pass / fail test.

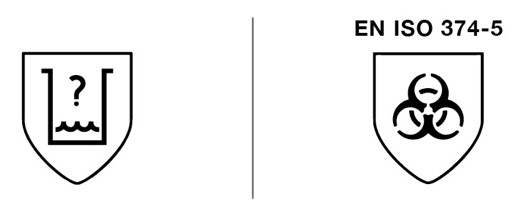

- If a glove only passes this test – water / liquid resistance and prevention of micro-organisms penetrating the glove – then it will carry the following 2 symbols:

Protection against Viruses:

- In the event that a glove is required to protect the wearer against Viruses, an additional test will need to be conducted.

- Should a glove pass this test,it will carry the folloiwng icon

Permeation:

- Permeation looks at the movement of a chemical through a glove on a molecular level – microscopic.

- The permeation test seeks to measure the amount of time it takes for a chemical to seep (permeate) through the glove. Once it has passed through the material (permeated) one can say it has penetrated the glove.

- This test is important as in the beginning, a chemical may not penetrate (move through) the glove. But over time – much like how a Helium balloon eventually deflates – the chemical may seep through the glove which can be very harmful to the skin.

- Based on the amount of time it takes a chemical to permeate (seep through) a glove material, it will get a rating between 1 and 6.

PERFORMANCE LEVEL | 1 | 2 | 3 | 4 | 5 | 6 |

BREAKTHROUGH TIME (min) | > 10 | > 30 | > 60 | > 120 | > 240 | > 480 |

- If someone is exposed to a chemical, they essentially have that amount of time to remove the glove before the chemical reaches their skin.

- If a glove has been exposed to a harmful chemical, it is recommended that the wearer first rinse their hands in a chemical basin and then remove the gloves.

- When a glove passes both the penetration test and the permeation test it will carry the following symbol:

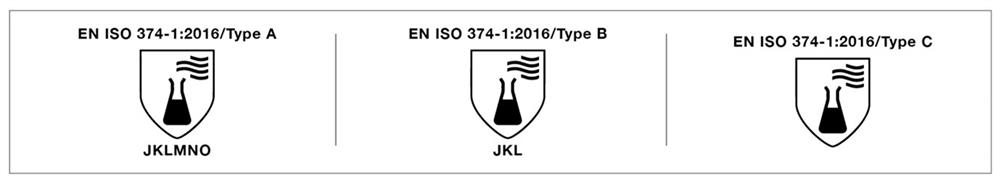

There are up to 18 chemicals that gloves can be tested against – refer table below. Depending on the number of chemicals that the glove has been tested against and how well it performs in the permeation test per chemical, the glove will be awarded a Type A | B | C

TYPE A: Permeation resistance of at least 30min each for at least 6 chemicals

TYPE B: Permeation resistance of at least 30min each for at least 3 chemicals

TYPE C: Permeation resistance of at least 10min for at least 1 chemical

The chemicals that pass the permeation test are then added underneath the symbol of the icon.

CODE | CHEMICAL | CLASS |

A | Methanol | Primary Alcohol |

B | Acetone | Ketone |

C | Acetonitrile | Nitrile Compound |

D | Dichloromethane | Chlorinated Hydrocarbon |

E | Carbon Disulphide | Sulphide-Containing-Organic Compound |

F | Toluene | Aromatic Hydrocarbon |

G | Diethylamine | Amine |

H | Tetrahydrofuran | Heterocyclic Etheric Compound |

I | Ethyl Acetate | Ester |

J | n-Heptane | Saturated Hydrocarbon |

K | Sodium Hydroxide | Inorganic Base |

L | Sulphuric Acid 96% | Inorganic Mineral Acid, Oxidant |

M | Nitric Acid 65% | Inorganic Mineral Acid, Oxidant |

N | Acetic Acid 99% | Organic Acid |

O | 25% Ammonia | Inorganic Base |

P | Hydrogen Peroxide 30% | Peroxide |

S | Hydrofluoric Acid 40% | Organic Mineral Acid |

T | Formaldehyde 37% | Aldehyde |

- This test seeks to understand how long it will take for a glove to degrade (experience changes in the glove material).

- There are various ways to identify whether a glove has experienced any degradation:

- Change in Colour | Flaking | Swelling | Hardening or softening of the material.

- The reason that this is important is that the permeation test looks at the resistance of a glove to chemical permeation (seepage) over a 30 min period. The degradation test looks at the change in the glove material over a 60 min period.

- I.e. it may take longer than 30min for a chemical to start affecting the state of the glove material. This test seeks to understand how much a chemical changes the structure and therefore protection of a glove material over 60 min.

- The test is conducted by measuring the force it takes to puncture the glove material before exposure to a chemical and then after exposure to a chemical.

Pienaar Brothers is a leading distributor of personal protective equipment in South Africa and proud stockist of uvex Gloves, Ansell Gloves and many others. To view our extensive range of gloves, click here.