There are multiple types of workers, such as welders and those working within foundries and kitchens, to name but a few, that are exposed to thermal risks whilst undertaking their daily job and it is therefore imperative that they are protected against the various degrees of the hazards that they face.

Whilst other standards within the hand protection category often require an explanation as to how or why a certain test is conducted to achieve a better understanding, EN 407 is a rather straightforward standard. It is comprised of 6 different tests that essentially test the performance of a glove against heat and/or fire risks.

A trick we use to remind ourselves of the six different tests is learning the saying: Flames can cause real men malaria:

- Flammability Resistance

- Contact Heat Resistance

- Convective Heat Resistance

- Radiant Heat Resistance

- Small Molten Metal Resistance

- Large Molten Metal Resistance

Each of the tests are rated on a level between 0 and 4, with 4 showing the highest levels of resistance.

a. Resistance to Flammability (0-4)

- Based on the length of time the material continues to burn and glow after the source of ignition is removed.

- People who need to worry about this are:

- Foundry workers

- Blacksmiths

- Welders

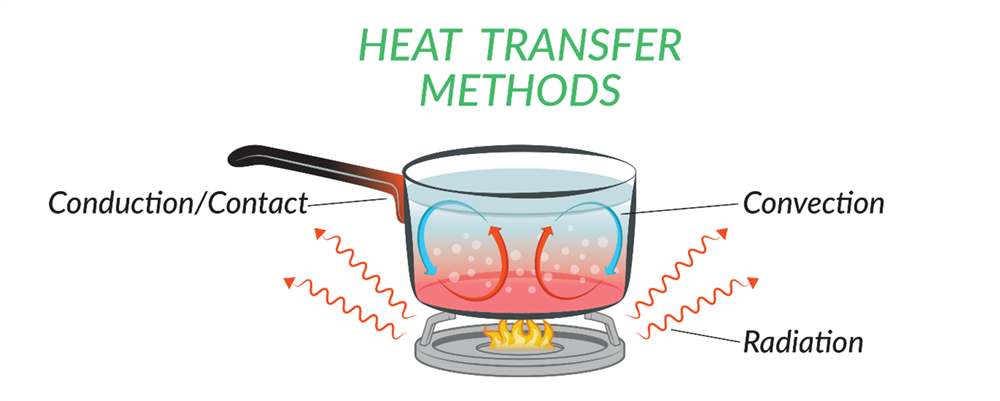

We find that the following image goes a long way in explaining the next 3 heat tests that are performed.

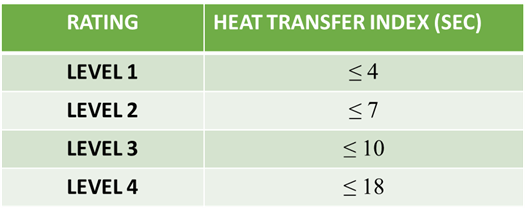

b. Contact Heat Resistance (0-4)

- Through conduction, heat can be transferred from one source to another, such as in the case of holding a steel pan with your hand or cupping a mug of freshly made coffee.

- Based on a temperature range of 100 C – 500 C a rating is given based on the wearer feeling no pain for at least 15 seconds when encountering the source.

- A performance level shall only be mentioned if a performance level of 3 or 4 was achieved in the flammability test.

- People who need to worry about this are:

- Chefs / Bakers

- Blacksmiths

- Foundry Workers

- Machinists

- Mechanics

- Welders

c. Convective Heat Resistance (0-4)

- When we talk about convective heat, we are looking at the transfer of heat from one source to another via the movement of a heated fluid such as water or air.

- The convective test seeks to determine the length of time the glove is able to delay the transfer of heat from the source, which is largely dependent on the thickness of the glove.

- A rating shall only be given if a performance level of 3 or 4 was achieved in the flammability test.

- People who need to worry about this are:

- Kiln Operation

- Foundry Workers

- Mechanics

- Welders

- Machinists

d. Radiant Heat Resistance (0-4)

- The definition of radiant heat can be a little technical at first, but when referencing examples of radiant heat, the concept becomes easier to understand.

- Radiant heat, also known as thermal radiation, is the transfer of heat from a hot surface through electromagnetic radiation. This type of heat does not require a body/medium to spread but rather heats the air and the bodies around that.

- Examples of radiant heat include the sun (you do not touch the sun for it to potentially burn you) or a fire in a room (you do not need to touch the flame in order to feel the heat within the room).

- The test is based on the length of time the glove is able to delay the transfer of heat when exposed to a radiant heat source.

- A rating shall only be given if a performance level of 3 or 4 was achieved in the flammability test.

- People who need to worry about this are:

- Autoclave Operators

- Foundry Workers

- Kiln Operators

- Mechanics

- Welders

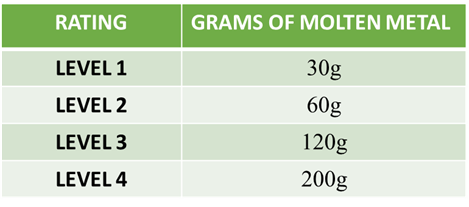

e. Resistance to Small Splashes of Molten Metal (0-4)

- This test examines the number of molten metal drops required to heat the glove sample to a given level.

- Typically, where a glove yields a good resistance level, the droplets of molten metal tend to run off the glove surface as opposed to sticking on it. As can be clearly deduced, this reduces the amount of time that the molten metal is in contact with the glove thereby lessening the chances of the glove temperature being raised to the threshold.

- A rating shall only be given if a performance level of 3 or 4 was achieved in the flammability test.

- People who need to worry about this are:

- Blacksmiths

- Foundry Workers

- Glazing

- Machine Maintenance

- Welders

- Glass Manufacture

f. Resistance to Large Quantities of Molten Metal (0-4)

- The test looks at the weight of molten metal required to cause smoothing or pin-holing across a simulated skin placed directly behind the glove sample.

- This test is failed if metal droplets remain stuck to the glove material or if the glove ignites.

- People who need to worry about this are:

- Blacksmiths

- Foundry Workers

- Welders

All EN 407:2020 rated gloves must also achieve at least performance level 1 for tear as conducted in the EN 388 test.

Pienaar Brothers is A leading distributor of personal protective equipment in South Africa and proud stockist of uvex Gloves, Ansell Gloves and many others.