D59 acid and flame garments are designed to protect wearers against the dangers of sparks, flames, & acid splashes. These garments are developed using a 100% cotton fabric that is chemically treated to protect the wearer against heat by self-extinguishing once the source of the ignition has been removed.

The environments that D59 acid and flame garments are worn in can be highly hazardous. As a result, it is imperative that workers are both comfortable in their garments and care for their garments in a manner that will not erode the chemical treatment before the required 50 washes.

This article looks at how to select and care for your D59 garments so that you can achieve the maximum benefit in both protection and longevity.

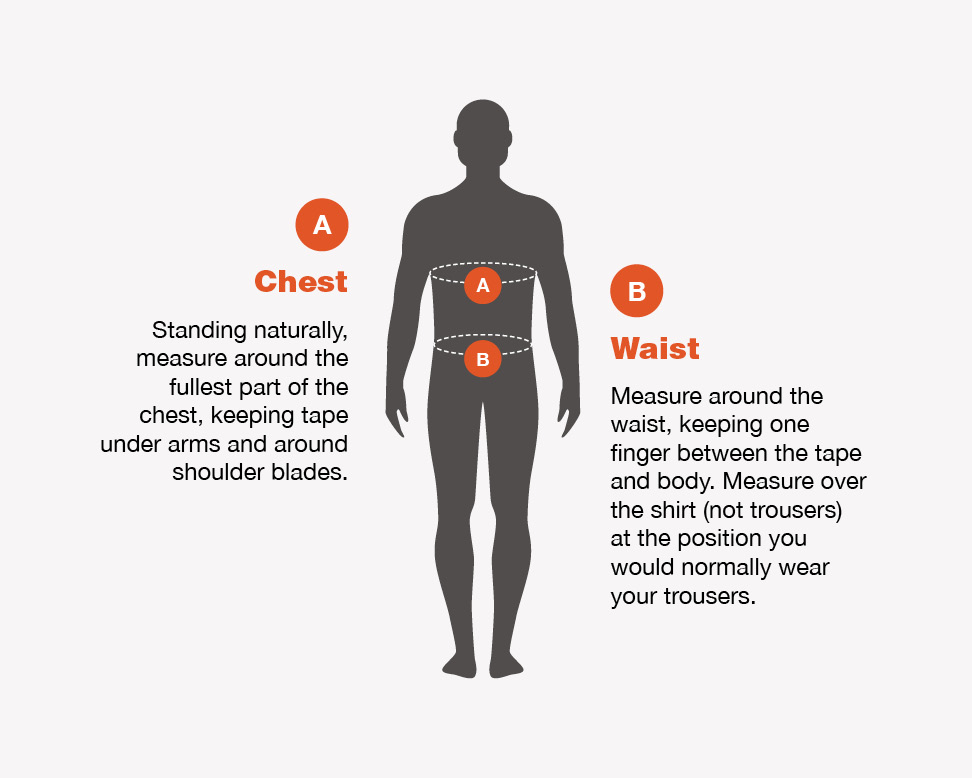

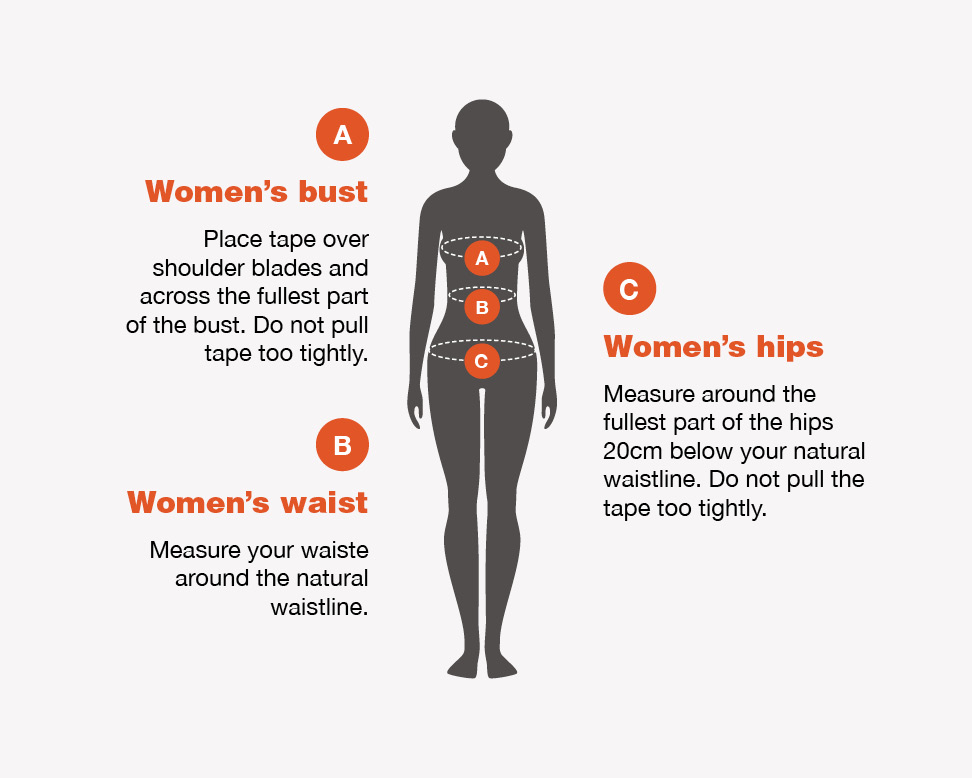

Step 1: Measure Where it Matters

The following 2 images show the exact areas that must be measured for both men and women to identify the correct sizing.

|  |

| Men | Women |

- When taking the measurements, never pull tight on the tape and always allow one finger between the tape and body. Cotton fabric can shrink up to 3% after a wash, so you need to allow good breathing room when taking the measurements.

All workwear garments come with a sizing chart. It is always recommended that you refer to the sizing chart to determine the right garment size and not base it on what you would typically order when buying your everyday clothing. We have included examples below.

| Dust Coats / Jackets / Golfers / T-Shirts | ||||||||||||||||

| Size | S | M | L | XL | 2XL | 3XL | 4XL | 5XL | ||||||||

| Chest CM | 81 | 87 | 92 | 97 | 102 | 107 | 112 | 117 | 122 | 127 | 132 | 137 | 142 | 148 | 153 | 158 |

| Chest Inches | 32 | 32 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 | 62 |

| Trousers / Jeans / Shorts / Boilers | ||||||||||||||||

| Size | S | M | L | XL | 2XL | 3XL | 4XL | 5XL | ||||||||

| Chest CM | 71 | 76 | 81 | 86 | 91 | 96 | 101 | 106 | 111 | 116 | 121 | 126 | 131 | 136 | 141 | 146 |

| Chest Inches | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 |

- You will notice a gap between the largest measurement under small (87cm) and the smallest measurement under medium (92cm).

- If your measurement falls between these sizes, round your measurement off to the nearest size:

- E.g. 90cm, order the size up – Medium or 92cm chest size.

- E.g. 88cm, order the size down – small or 87cm chest size.

- It is always recommended that you purchase jackets and trousers separately, but if jackets and trousers are supplied as a set, it is recommended that you order based on the chest size. Be sure to inform the supplier of this to avoid confusion.

- When placing an order for Boilersuits, use the waist measurement. It is always recommended that you order your boilersuit 1 inch size up from what your measurement is to enable comfort and flexibility. I.e. if you are a 32” waist, order a 34” boilersuit.

Step 2: Accreditations are More than Just a Number

There are various standards a garment must be tested against to offer the full protection that D59 acid and flame garments were developed to offer in South Africa. Always refer to the spec sheet to ensure that your garments carry these accreditations and are not merely compliant to the standards:

- SANS 1423 Part 1 – 1987, the garment has been tested against the requirements of textile fabrics of low flammability.

- ISO 6530:2005, the protection against liquid chemicals in accordance with the DIN 32763 specifications and requirements.

- EN / ISO 20471 | ISO 116612 | ISO 14116 | EN 469, with regards to the performance of reflective tape when exposed to flame.

- SANS 1387, which applies to woven cotton and similar fabrics in terms of weave and grams per square meter. The minimum requirement for a D59 garment is drill material with a 4/1 satin weave, 270g/m2.

- SANS 434, which specifies the requirements for the material, cut, make and trim of boiler suits, two-piece work wear suits, bib and brace overalls and unlined jackets that carry the SABS approved mark.

- ISO 90001, indicating that the manufacturing facility itself has been audited and approved by the SABS.

Step 3: Not all garments were created equal:

When you refer to the specification (spec) sheet of a garment, it should tell you what the GSM (grams per square meter) of the garment is. E.g. 270 gsm / 285 gsm / 300 / 320 gsm. This is used to determine the weight and thickness of a fabric. A higher GSM is often associated with a stronger garment.

The following factors can affect the overall GSM of a fabric: Fiber type, Yarn Weight, Weave, Finishing process.The reason the GSM in one D59 garment may differ to another could be because of the thickness of the cotton yarn used in the two garments and / or how tightly the yarns were woven together.

- In principle: The thicker the yarn, the higher the GSM of a fabric. The more tightly the yarns are weaved together, the higher the GSM of the fabric.

For heavy duty applications, one should especially consider the GSM of a garment as it may impact the durability and longevity of a garment. If you are finding that your garments are being damaged well before the 50 wash cycle, you may want to increase the gsm of your garment.

The specification sheet should further advise on the type of stitching used in a garment. This typically ranges from single stitched garments to triple stitched garments.

- In areas where the body is stretched / bent putting pressure on the seams (buttocks, inner thigh, under the arms, across the upper back), the higher the stitching, the stronger and typically longer lasting the garment will be.

Some manufacturers also offer bar-tacking on stress points (pockets, zippers, belt loops), which is an additional stitch on the side areas of the pockets to make it more durable.

Step 4: Consider the Number of Washes

A D59 garment should be able to undergo 50 washes (if the wash care instructions are followed) before it needs to be replaced. There are 52 weeks in a year. If a person washed their garment after every shift (5 shifts per week), the number of garments (Jackets & Trousers) issued per employee, per year should be worked out as follows:

- 50 weeks in a year = 5 garments (250 days)

- 40 weeks in a year = 4 garments (200 days)

- 30 weeks in a year = 3 garments (150 days) etc.

The life span of a garment can be improved if care is taken to ensure buttons are fastened and zips are closed during the washing process. When garments are left open, the zippers and buttons can get caught on the fabric which leads to tears and even ripping.

Step 5: Follow the Wash Care Instructions

When it comes to treated garments, it is imperative to follow the wash care instructions. To pass as a certified D59 acid & flame garment, each garment is tested in a laboratory under strict wash care instructions. If the wash care instructions are not followed, then the treatment used to protect the wearer against acids, flames, sparks, metal spatters etc. can erode leaving the worker exposed to these harmful hazards.

Typical wash care instructions include:

- Pre-treat greasy stains.

- A warm wash at 40 Degree Celsius.

- A warm iron on a damp garment to reignite the flame-retardant finish that is applied to the fabric.

- Do not tumble dry.

- Do not apply bleach or detergents that contain bleach.

If a garment is exposed to a harmful chemical, it must be washed and neutralised as soon as possible to prevent the chemical from destroying the fabric, causing holes which fray wider over time.

Step 6: If You are Unsure, Just Call

Keeping your workforce safe in an industrial environment requires understanding many standards and applications. This can get confusing and even overwhelming at times.

As a leading distributor of PPE, we are always a phone call away. Feel free to reach out to us with any questions and together with our partners, we will ensure you receive the help that you need. We provide detailed training to workers, buyers and washing bay staff on how to improve the life span of your garments to safeguard workers and save on costs.